Printing

Last week we focused on describing the prepress process. We continue to tell the story of the packaging’s journey by introducing the printing process.

The operator sends the verified print files to the machine via cloud service to set up the printing press. The machine automatically calibrates itself and sets itself into working mode, calculating the parameters of the work at hand while at it (colour mode, paper type, format etc.). The last word, before work begins, is with the printer who, using previous work experience, verifies all details and corrects them when necessary.

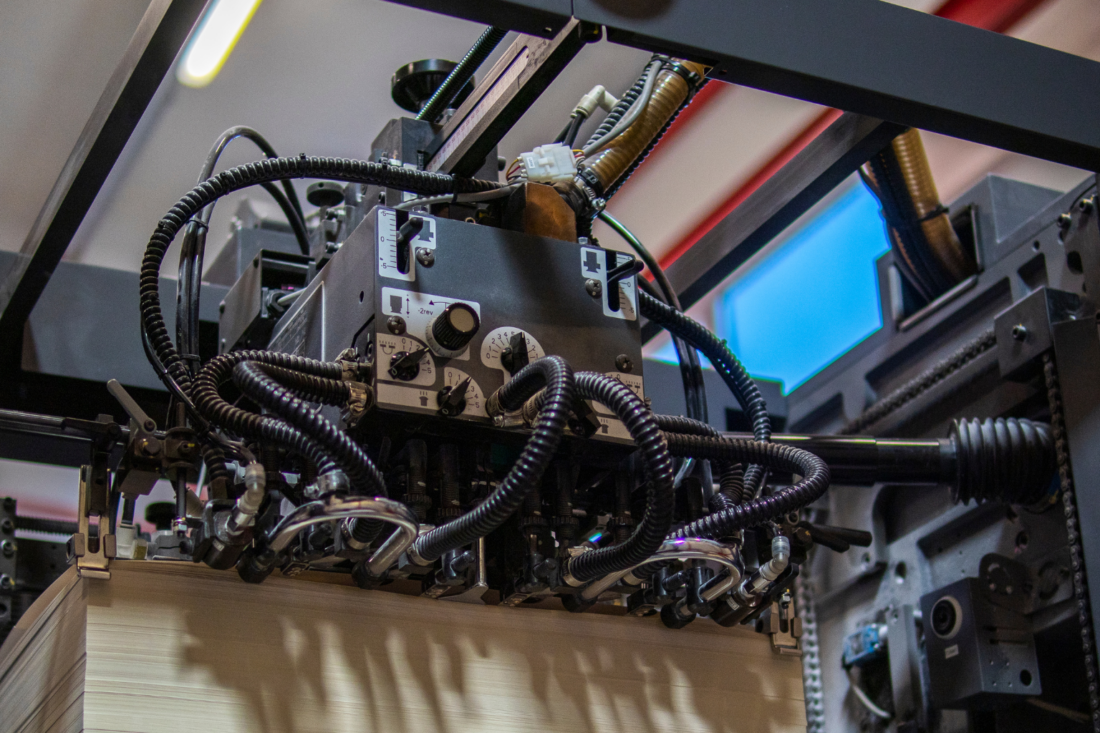

At Ecoprint, we use the A1 format five-colour (CMYK + PANTONE) offset printing machine, which is supplemented by water-based varnish and special IR drying sections. Thanks to a larger format, we can fit many images on a single sheet. This helps us save time, energy and quantity of paper used in that work.

The sheets (cardboard or corrugated paper) are placed at the mouth of the machine, and then pulled in one by one. The offset printing machine has five colour sections used to apply the different dyes. The paper, after being fed into the machine, moves through the sections when the dye is applied to the sheet using the dies.

After the dye has been applied in the printing section, the material moves onto the varnish section. Ecoprint uses a water-based varnish in its production. A water-based varnish is an environmentally friendly protective layer that gives a matte or glossy finishing to the print.

The final activity in the machine is the IR (infrared) drying. This helps us shorten the drying time for the sheets, which in turn enables us to start post-processing earlier. It is important to notice that the above-mentioned printing process happens very quickly—approximately 12,000 units per hour. While this is happening, printers are continuously checking the overall quality of the work, such as dot gain, registration mark precision etc. The entire above-mentioned process is carried out in order to offer printed materials corresponding to client’s wishes and the established quality requirements.